Table of Contents

ToggleBreathe Easy The Ultimate Guide to Engine Air Filters for Your Truck

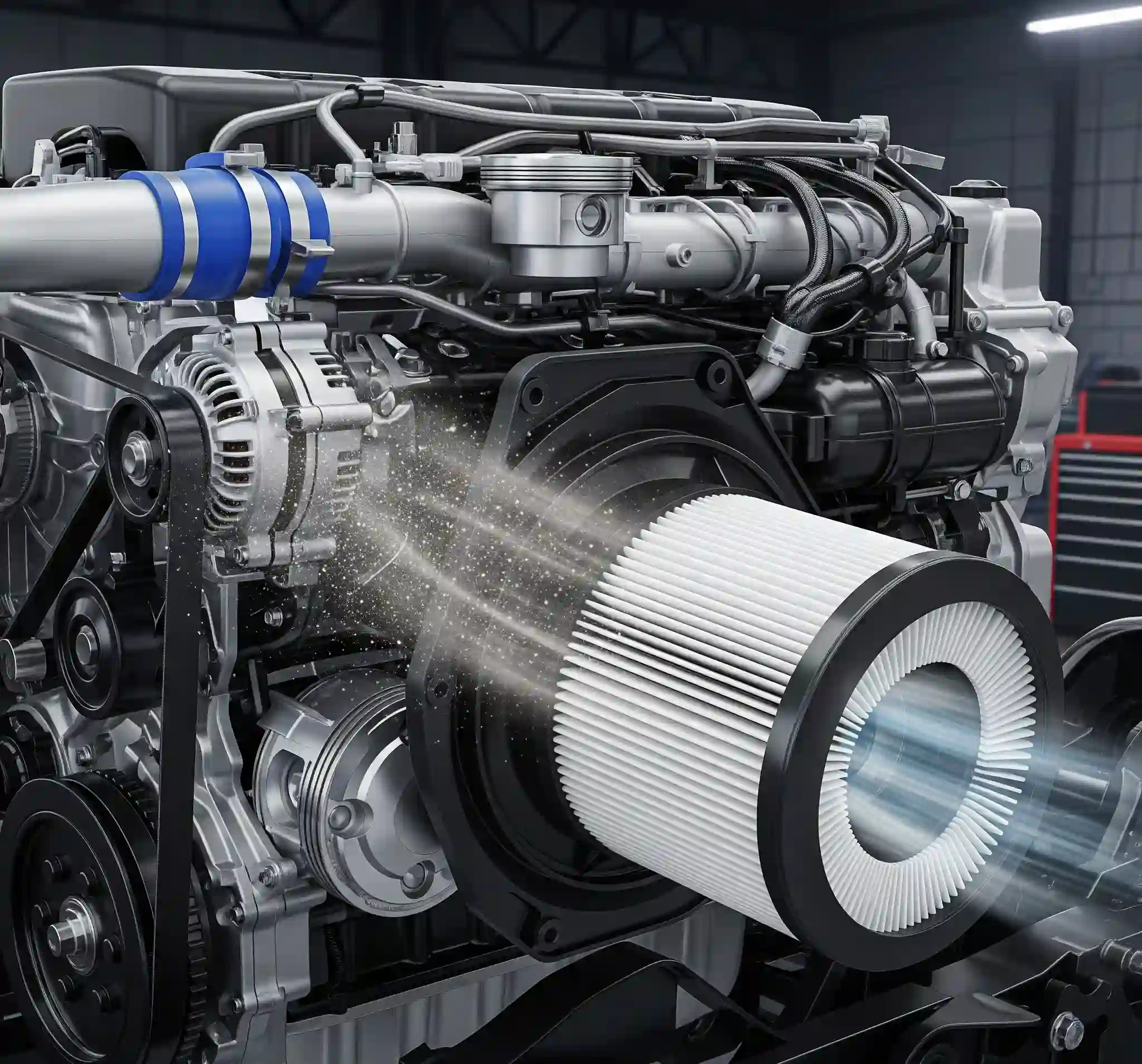

Think of the engine in your American truck as a world-class athlete. To perform at its peak, delivering maximum power and endurance, it requires fuel, proper lubrication, and something just as vital: a massive, constant supply of clean air. For every gallon of diesel it consumes, a heavy-duty engine can inhale up to 15,000 gallons of air. But the air on our highways, construction sites, and agricultural roads is far from clean. It’s a cocktail of dust, pollen, soot, and abrasive particles.

This is where one of the most critical components under your hood comes into play: the engine air filter. It may seem like a simple, replaceable part, but it serves as the lungs of your powertrain, performing the non-negotiable task of protecting your multi-thousand-dollar engine from a constant onslaught of contaminants.

Here at the American, we don’t just produce spare parts; we engineer peace of mind. We understand that engine longevity and performance are paramount. This comprehensive guide will delve into the world of Engine Air Filters, explaining why they are so crucial, how they are constructed, and what you need to know to ensure your truck breathes clean for the long haul.

The Abrasive Enemy Why Clean Air is Non-Negotiable

To truly appreciate the engine air filter, you must first understand what it’s up against. The primary enemy is silicon dioxide, or silica—the main component of sand and dust. These microscopic particles are incredibly hard and abrasive. When ingested into an engine, they act like liquid sandpaper, accelerating wear on the most critical internal components:

- Pistons, Rings, and Cylinder Liners: Abrasive particles get trapped between the piston rings and the cylinder walls, scouring the precision-honed surfaces. This leads to a loss of compression, increased oil consumption (blow-by), and a significant drop in engine power and efficiency.

- Turbochargers: The compressor wheel in a turbocharger spins at speeds exceeding 100,000 RPM. Even the smallest hard particle striking these precision-balanced fins can cause imbalance, erosion, and eventual catastrophic failure.

- Valves and Valve Seats: Contaminants can prevent valves from seating properly, causing leaks, burned valve faces, and poor engine performance.

- Sensors: Modern engines rely on sensitive components like Mass Airflow (MAF) sensors to calculate the correct air-fuel mixture. A dirty or damaged sensor will send incorrect data to the ECU, leading to poor fuel economy and increased emissions.

The cost of a high-quality engine air filter is minuscule compared to the cost of a premature engine overhaul. A clogged or inefficient filter doesn’t just risk damage; it also slowly suffocates the engine, forcing it to work harder to draw in air. This increased effort, known as restriction, directly translates to reduced horsepower and wasted fuel, costing you money at the pump every single day.

Anatomy of a Heavy-Duty Engine Air Filter

What separates a premium filter from a subpar alternative? The difference lies in engineering, materials, and construction. A heavy-duty air filter is more than just paper in a can; it’s a highly engineered system.

The Filter Media The Heart of Filtration

The core of any filter is its media. For heavy-duty Engine Air Filters, this is typically a specialized blend of cellulose (paper) and synthetic fibers. This material is engineered to be porous enough to allow air to pass through freely but dense enough to trap harmful particles.

- Pleating: You’ll notice the media is always pleated, folded into a tight accordion-like pattern. This isn’t for looks; it’s a brilliant piece of engineering that drastically increases the total surface area of the filter within a compact housing. More surface area means two things: better airflow (lower restriction) and a much higher capacity to hold dirt before it needs to be replaced.

- Efficiency Rating: High-quality filters are rated for their efficiency. A rating of 99.9% means the filter media can trap 99.9% of incoming contaminants. This is often measured against specific particle sizes, with premium filters capable of stopping particles as small as 70 µm` thick.

The Sealing Gasket The Unsung Hero

A filter is only as good as its seal. The gasket, typically made of a durable and pliable polyurethane, creates an airtight seal between the filter and its housing. If this seal is compromised—cracked, hardened, or improperly seated—dirty, unfiltered air can bypass the filter media entirely. This “dusting out” an engine can cause severe damage in a very short amount of time. This is why you should never settle for a filter with a flimsy or poorly constructed gasket.

Structural Integrity Built to Withstand the Pressure

The forces inside an air intake system are immense. A heavy-duty filter needs a robust structure to survive.

- Inner and Outer Liners: A mesh screen, usually made of expanded metal, lines the inside and outside of the pleated media. This framework prevents the pleats from collapsing under the intense vacuum created by the engine and turbocharger, ensuring consistent airflow.

- End Caps: Durable metal or molded plastic end caps bond the media and liners together, creating a rigid and stable final structure.

Most modern American trucks use a radial seal design. This means the gasket seals around the circumference of the filter outlet, providing a reliable, 360-degree seal that is superior to older axial seal designs.

Performance Metrics What Defines a Superior Filter?

When selecting an engine air filter, three key performance metrics matter most. The best filters provide an optimal balance of all three.

- Efficiency: As mentioned, this is the measure of what percentage of contaminants a filter captures. For the ultimate protection of modern, tight-tolerance engines, you should never accept anything less than the highest efficiency available.

- Capacity: This is the total amount of dirt the filter can hold before it reaches its maximum restriction level. A high-capacity filter means a longer service interval, saving you time and money on replacements. The depth and number of pleats are major factors in capacity.

- Restriction: This refers to the resistance to airflow, often measured in “inches of water column.” Every filter has some initial restriction when new. As it collects dirt, this restriction increases. The ideal filter has very low initial restriction but high dirt-holding capacity, allowing the engine to breathe freely for as long as possible. A filter that is highly efficient but also highly restrictive from the start will rob your engine of power.

At the American, our Engine Air Filters are engineered to excel in all three areas, providing maximum protection (high efficiency), long life (high capacity), and optimal engine performance (low restriction).

Maintenance Knowing When to Change Your Filter

How do you know when it’s time for a replacement? Guessing is not a strategy.

- The Restriction Indicator: The single most reliable tool is the air filter restriction indicator (or filter minder). This simple gauge is connected to the clean side of the filter housing and measures the vacuum level. As the filter clogs with dirt, the vacuum required to pull air through it increases. The indicator will show when the restriction has reached the manufacturer’s recommended limit (e.g. inches of H₂O), signaling that it’s time for a change. Using the indicator ensures you get the maximum possible life out of every filter without ever putting the engine at risk.

- Scheduled Intervals: Refer to your truck manufacturer’s service manual for recommended replacement intervals based on mileage or operating hours. These are good guidelines, especially if your truck lacks a restriction indicator.

- Visual Inspection: While a filter can be at the end of its life long before it looks “dirty,” a visual inspection can reveal damage to the media or seals that necessitates an immediate change.

A Critical Warning: Never Clean a Paper Air Filter You may have seen old-timers tapping a filter on a tire or, even worse, using compressed air to blow it clean. Do not do this. This practice will permanently damage a modern filter. The high-pressure air creates microscopic tears in the filter media, rendering it useless. These invisible holes will allow damaging abrasive particles to pass directly into your engine. Always replace a dirty filter with a new, high-quality one.

The American Your Partner in Engine Protection

The engine air filter is an inexpensive insurance policy for the most valuable asset in your truck. It is the silent guardian that works tirelessly on every mile of every haul. Compromising on its quality is to gamble with engine performance, fuel efficiency, and ultimately, its very survival.

Choose protection. Choose performance. Choose the durability your American truck deserves. Explore the complete line of heavy-duty Engine Air Filters from the American and give your engine the clean air it needs to run stronger, longer.